It is now 20 years since I saw my first Formula Student event, FSAE 1994 at the Pontiac Silverdome in the US. I was on a business trip in the USA and attended as a spectator.

Pontiac Silverdome where the FSAE competition was held in the car park for many years.

Over the years it has been interesting to watch the development of the teams as much as the development of the cars themselves.

New teams enter the competition and usually they are much better than the new teams of ten or fifteen years ago, and the new FS events being set up all over the world are better than those early events run in the US and the UK.

Even though the teams have access to better information about Formula Student, forming a team and building and competing with a FS car, thanks to the internet, I still see some fundamental traps that teams fall into. But that is good! remember, FS is an educational program and the best lessons ever learned are those from your own mistakes.

I will list procrastination as the first of the repeated errors I see. Procrastination is one of a family of errors all coming under the heading of poor project management. Procrastination has some friends like ‘Indecision’, ‘Vacillation’ and a real sneaky one called ‘Analysis Paralysis’.

Bluntly, if the team don’t get the car finished in time they won’t even get to the competition and if they do, they will certainly not be competitive.

Each year we see teams arrive with unfinished projects. There are always excuses. ‘We have no money’, ‘We have only a small team’, ‘The University doesn’t support us’ etc, yet at the same competition there will be teams with less money, a smaller team and no college support competing competitively. These are the teams who have learned not to procrastinate.

I mentioned ‘Analysis Paralysis’, a very common failing in teams. They start a design project, not really knowing what they are doing and then over analysing the design, just chewing up time. You cannot analyse something you do not understand!

A team must get their car finished early and test the heck out of it. Until they understand what the vehicle is doing they will never be able to close the link between the theoretical and the practical.

This is an area where the experienced teams gain an advantage over the newcomers.

The second issue I see with new teams is ignorance, particularly ignorance of the FS Rules. So often we seen an otherwise exemplary car fall foul of the regulations and is either not permitted to compete or is so compromised by adapting it to meet the rules, that it can never be competitive.

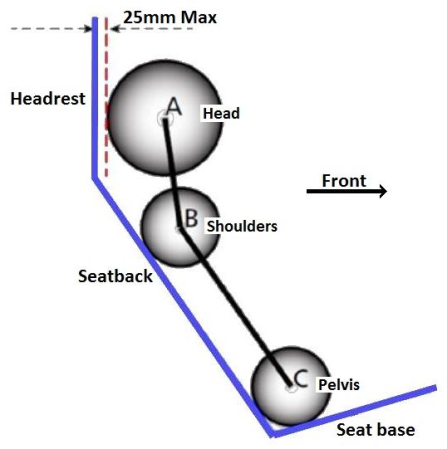

Roll hoops, side impact structure, crash attenuator etc. must meet the requirements of the current rulebook. The templates must fit and the 95th percentile male and 5th percentile female must fit and be able to operate the car. The 'Percy' mannikin template must fit and the roll hoop clearance for 'Percy' and all your real drivers must be compliant.

If you think about it, Ignorance is often related to procrastination! If a team commits either of these sins, they will fall at the first hurdle of any competition and will essentially have wasted a whole year’s effort!

Incidentally, ignorance of the rules is often exaggerated by ignorance of the procedure set in place to enlighten teams about the rules. Questions about legality can only be answered by the Rules Committee of the event a team intends to answer. Opinions gained on internet forum sites like fsae.com are only opinions and have no real status.

Another form of ignorance is failing to understand what the Formula Student competition is all about.

The task given is for the team to design a prototype car for mass production. This means the design must be sustainable. The company who would mythically build these cars would need to make a profit in order to succeed. Any team with a big enough budget and enough resources can build a spaceship, but is it a justifiable design for the competition?

And, although we need to be environmentally aware, nowhere in the rules is it written that the intent of Formula Student is to ‘save the planet’.

In the dynamic events, the enemy of good handling and roadholding is compliance. I am talking here about compliance in the structure. Compliance in the team members often leads to procrastination.

Compliance in rear wheel toe control is an abomination in the eyes of the judges! Many of the cars we see have rear toe compliance issues and almost as many have toe compliance issues at the front wheels! Lack of toe control is often evidenced by the characteristic wear marks left on the tyre tread.

An example of poor rear toe control and chassis compliance

Rear toe compliance will make the car virtually undriveable at the cornering loads seen in competition. No matter how good the driver is, he cannot drive competently if the car is fighting him all the way. The control feedback loop must be as ‘pure’ as the designer can make it. Really, it probably doesn’t matter too much if the car has some handling quirk as long as it is predictable, repeatable and the driver understands it.

The usual cause of toe compliance is a narrow toe reaction base or the toe control link is angled or not supported properly at its chassis mount. Part way along a wishbone arm is not a suitable reaction point for a toe compliance link! Rear toe control links should be at right angles to the centreline of the chassis and anchored at a stiff chassis point.

Of course, kinematically, the operation of the suspension should not cause the toe link geometry to steer the rear wheels (unless, of course, the designer actually wants it to steer), but we are talking about compliance issues here.

At the front of the car we see toe compliance as incorrect angling of the tie rods, flexible or poorly mounted steering arms, flexible uprights or flexible steering rack mountings. This latter is very evident if the team choose to use a centre mounted rack and pinion unit originally designed for a junior dragster or something similar. The rack housing must be properly supported at the ends, because the steering arm s will impose significant bending loads to the rack and its mountings when the car is steered.

A design decision the teams have to make is whether to place the more heavily loaded tie rod in tension or compression from the steering forces. This in turn will determine whether a steering rack should be mounted ahead or behind the front axle line.

In an effort to pass the foot-well template test, some teams will use bell-cranks or drop links in the steering mechanism. I have no objection to such a design if properly implemented, but most I have seen have been very compliant, either torsionally, in bending or in the mounting brackets.

To understand the effect of compliance in the steering mechanism, imagine trying to drive competitively in a car with a rubber steering wheel! The effect is the same, compliance in the steering system.

Camber control features very high on every FS designer's agenda. Teams spend enormous amounts of time defining camber curves to get the optimum grip from tyres. All this carefully designed camber control goes out the window when compliance sticks up its nasty little head. The usual source of compliance is simply poor design, meaning the designer has not studied the load path from the tyre contact patch and how they are reacted in the chassis.

Most chassis we see probably do meet minimum stiffness requirements, but they are let down by poor suspension link design and attachments. I have shown photographic proof of poor camber control to designers who flatly refuse to believe what they see, blaming some photographic anomaly or other distortion. They claim it is physically impossible for the wheel to adopt that camber angle based on their kinematic design. I call this the ‘Cleopatra Syndrome’ (the queen of denial)!

The usual cause is poor suspension to chassis joints, either the loads are not fed into a node or the brackets used to  adapt to the chassis are flexible or poorly mounted. Sometimes the fault lies in the suspension arms and the old nemesis ‘Rod ends in bending’ can be a part of this. Another source of potential loss of camber control is a lack of stiffness in the uprights or spindles or even in the wheel itself.

adapt to the chassis are flexible or poorly mounted. Sometimes the fault lies in the suspension arms and the old nemesis ‘Rod ends in bending’ can be a part of this. Another source of potential loss of camber control is a lack of stiffness in the uprights or spindles or even in the wheel itself.

A dangerous source of camber compliance is flexibility in the wheel or the hub it is bolted to. This flexing is cyclical and can often lead to a failure of the wheel, hub or axle. It is the usual cause for cars to lose wheels in competition.

Loss of camber control permits the tyre to roll over on its outside edge. Apart from the loss of grip, the tyre quickly overheats and sheds rubber.

Another issue that plagues newer teams is poor ergonomics. The driver can never perform well if he cannot operate in a comfortable environment. Certainly, 'Percy' the standard driver mannikin, must fit and the 95th percentile male and 5th percentile female must be able to operate the vehicle, but only the team drivers have to race the car. It is imperative they have a suitable working environment.

An example of very poor ergonomics

The drivers should fit the car, their body should be supported laterally from above the knees to the shoulders. Moulded personal seats are a good idea and the car should be so comfortable to sit in the driver often goes asleep in there. Seriously!

There should be no chassis tubes, brackets, cables or controls that the driver can contact when the car is in motion. The worst offending component for many years was the steering rack. Many designers would locate the steering rack where the driver had to thread his legs underneath it in order to drive the car. The Tech Inspectors called them ‘shin breakers’ and the Design Judges refused to reward them with good Design points, regardless of how good the rest of the design might be. The continuance of these ‘shin breakers’ was what prompted the introduction of the foot-well template rule.

An example of poor steering rack positioning prohibited by the rules.

The template has hugely complicated the design of the car, particularly in the area of steering and has contributed a lot to the steering and toe compliances mentioned earlier.

It might be just my impression, but there seems to be a lot of favour out there for tiny steering wheels. I am sure this is a hangover from the computer games and driving simulations many teams use to train drivers..

Ergonomically a slightly larger wheel will give better control. There may be an issue with space in the cockpit, but that should be addressed at the design stage and there are many flat top/flat bottom racing wheels out there.

The team doesn’t need a carbon fibre wheel with more computer memory than was required to land a man on the moon! The rules require a quickly detachable steering wheel hub. A loose hub that allows slop in the steering system is another source of compliance mentioned earlier and make accurate placing of the car very difficult.

Compliance and outright dangerous construction in the pedals, pedal box and master cylinder mounts is often seen, primarily because inexperienced teams have no good idea of the magnitude of cockpit forces.

Brake pedal compliance is directly related to lap times! The driver needs to have complete trust in the braking system. A properly designed brake system will have the pedal rate ‘rise’ until the brakes are fully applied. Having a ‘falling rate’ pedal is often described by the driver as having the pedal ‘fall away’ when the brakes are applied.

The lack of positive feedback confuses the driver regardless of whether the source is the pedal ratio, hydraulic mismatch or pedal box compliance. The pedal system should be able to react a pedal force of 1,500N with no failures and minimal compliance.

It is understandable, but newer teams should be cautious about copying features from another car without understanding the reasoning behind their design. We see this at every competition and it is referred to as 'Monkey see, monkey do'!

A classic example is the wholesale adaptation of single cylinder engines following the success of teams like RMIT, Delft and GFR. A close inspection of those teams shows the adaptation of the single was only part of their design concept, yet some teams simply attempt to plug in the little engine where a big one used to be. The result is a heavy slow car that is difficult to drive.

Another example is the wholesale adaptation of carbon fibre composites, even where their use is inappropriate. Often, the teams have no experience with the material but are of the opinion it is necessary in order to dazzle the judges. Let me state categorically, that is not the case. In fact, inappropriate use of composites will cost the team points in the Design part of the competition.

A good example is the favoured use of carbon fibre road wheels. If a team present a car with carbon wheels, they better have a really good justification. When the Judges add up the pros and cons, it can be very difficult to justify carbon wheels. A good defence of the decision does not include statements like ‘They are cool’ or ‘We did it because we could’.

The Rules require the teams to submit an eight page Design Report and a two page Specification Sheet to the judges prior to the event.

The Design Report is the introduction of the car to the Design Judges. The intent of this is twofold. First, it is to prepare the Judges prior to them seeing the car. Second, it is an exercise in training team members about the reports they will have to live with when they graduate to industry.

Sadly, many Design Reports are lacking in content and quality. The usual reason is the team have not allocated time and responsibility for the DR and it ends up being thrown together at the last minute.

Even worse, sometimes with teams presenting a ‘legacy car’ (a car that is several evolutions away from its original design) the DR is the same document submitted last year and possibly even the year before with minimal editing to change the date etc! This is insulting to the judges and tells them a lot about the culture within the team.

It has been said many times ‘You only get one chance to make a first impression’. In FSAE, this chance is the Design Report and teams should avail themselves of this opportunity to score well in the Design Event!

The DR is not a marketing document. It is a briefing document from one group of engineers (the team) to another group of engineers (the Judges) to inform them about their design and to justify their design decisions. It is not a place for hyperbole and fancy marketing statements.

There is a specified format for the Design Report. Four pages of text, three view drawings and a single ‘free’ page. The tree view drawings should be just that, drawings! Not low resolution screen dumps from a solid modelling program. There should be enough detail that the judges can see and understand the design, see the structural load paths etc.

A companion document to the Design Report is the Specifications Sheet.

Again, this is in a specified form and there is an instruction to the team not to reformat the document! Quite often we see a spec sheet which doesn’t seem to describe the same car as the Design Report! I am not sure how this happens, but when it does, it will affect the team's design score.

As I said at the beginning of this article, I do not see the errors new teams make as a bad thing. These are lessons learned that will stay with the students for life. Just one more of the educational advantages of Formula Student Germany.

I hope this gives the reader an insight into some of the challenges faced by newer teams that are not so obvious to the casual observer.

Pat Clarke

Chief Design Judge FSG 2014