It has been a little while since my last column, due primarily to work pressures, but now we have FSAE Michigan out of the way, I can concentrate on FSG again.

Congratulations to Oregon State University on winning both Design and the competition at MIS. It will be interesting to see how their Global Partners, Ravensburg, get on in Hockenheim.

I would also like to welcome FS Austria as the newest member of the global Formula Series. Meanwhile, back at Pat’s Corner…

Motor Racing is Dangerous!

Motor racing is dangerous….so it says, right there on the ticket at every motorsport event!

Life is dangerous, but when we start to push the envelope, as in motorsport, then things can get uncomfortable very quickly.

University administrators are aware of this, after all, they are the people who negotiate the insurance premiums. This is why some Universities do not permit participation in Formula Competitions.

When a team ignores safety in the workshop, on the test track or at the competition, they jepoardise their permission to compete. When they record this ignorance (or stupidity) in the media, they jepoardise many other teams.

Recently we have had a few notable instances. The video posted on Youtube by the Thai team testing their impact attenuator by crashing into an excavator bucket is the most blatant example I have seen.

That the students would do such a thing is unthinkable. That they would post their stupidity for the world to see is beyond belief. When stuff like this seen by University administrators, it colours their perception of what Formula is all about, often with catastrophic results for innocent teams who have no involvement with this behaviour.

So we sit here ‘tutt tutting’ about the silly Thais… but has your team done something as stupid?

A five minute search found many examples of Formula Stupidity!

Here are two frames from posted videos showing FS cars getting sideways in car parks whilst in close proximity to other vehicles. The driver on the right is not wearing a helmet or protective wear..

This sort of behaviour gives college administrators apoplexy! Remember, this activity is going on mostly in cars that have not been through any proper Tech Inspection!

If you think about how many cars get rejected at their initial tech inspection for potentially dangerous faults the team could not recognise, you can see why those of us charged with a ‘Duty of Care’ for the students we are advising get nervous.

Here is a picture showing what can happen. There are a couple of things to note in this picture. First, look at the sensible and safe footwear being worn and secondly, look at the bent brake pedal! The amount of pressure a frightened driver can put into the brakes is usually underestimated. We have mentioned weak and flexible brake pedals before in this series.

‘Motor racing is dangerous’ does not just apply to driving the car. A particular source of danger is in the workshop or in the construction or preparation of the car.

How often do we see someone grinding without eye protection? We have seen people welding without eye protection! They line up the torch and then shut their eyes and strike the arc! I also see this on TV Hotrod and Biker build programs, so maybe students are trying to emulate these tattooed bozos?

God almighty, do you realise how dangerous that is? You are only issued with two eyes and replacements are not available.

I have seen guys sawing or grinding fibreglass or carbon bodywork without a breathing mask. Let me tell you, inhaling glass or carbon fibres will introduce you to an ongoing life of pain and misery!

Recently, this picture was posted on FSAE.com for all to see.

The team are trying to pull a carbon tube off the mandrel. Obviously the mandrel was made with no draft (taper) and the correct release agent hasn’t been used.

They admit to having broken winches trying to pull the tube off!

When that thing lets go, as sooner or later it surely will, anyone standing nearby can expect to be in hospital with similar injuries to Valentino Rossi! OHS regulations are there for a reason!

Each team should have a dedicated OHS officer who is tasked with keeping the team personnel safe. There are many OHS (Occupational Health and Safety) sites on line for guidance.

Pat’s Design Error of the Month

I try to choose a Design Error that relates to the column above. This month I have focussed on a mistake that will not get through Tech Inspection, but teams will test with the car in this condition.

The results of even a minor crash could be very painful, possibly even fatal… a word I hate to use!

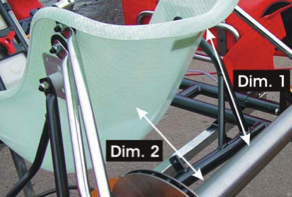

It usually occurs when a team choose to adapt a go kart seat to their car.

They often use simple struts from the chassis to the seat. In the event of a crash or even heavy side loading the strut can come through the seat and stab the driver. Flexing of the seat will cause the material to fret around the bolt holes enlarging them. The result is the strut could come through the seat even in normal driving.

In the example above, the bottom strut is easily seen, the side strut is obscured by the shoulder belt, but the problem can easily be seen. In the example below, the struts cannot be seen, but the threaded ends of these mounting struts can be seen, aimed directly at the driver’s heart and lungs!

If you must use a kart seat (and I don’t recommend it for reasons I will cover in a future column) then you must put some ‘anti intrusion’ plates on the outside of the seat to prevent the struts penetrating. At the very least these should be large flat washers, but a better solution is to use a specially formed metal plate bolted, riveted or bonded into the seat as shown here in a picture from Steve Tillett’s kart seat company installation instructions.

So, until next time, keep safe by thinking about what you are doing and acting accordingly. Remember, one dumb act by a team member could hurt someone at worst or even cause your University to take away your permission to compete!

Pat

PS, I wonder if the Thai team replaced their harness after their impact test? The Safety harness is a ‘one use’ component that must be replaced after ‘use’.