Well, 2011 has passed into history, so we are all a year older and hopefully a year wiser. I wish all teams around the world, the very best wishes for the New Year 2012. Whether you are building a FSC or FSE car, or a hybrid car for some other competition, remember, time is finite. I cannot believe how fast 2011 passed us by, so stop procrastinating! Time is short! Get to work. That goes for me too!

Formula SAE Australasia 2011

The last competition of 2011 was FSAE Australasia 2011 held near Melbourne on the weekend before Christmas, a week or so later than in the past. It was one of the most interesting Australian competitions to date. A combination of different conditions meant the event was the most competitive on track event ever. Blustery wet and windy weather made on-track tactical decisions critical as teams tried to get their best drivers on the track at the best times without incurring the time penalty for running out of order.

For the second year running, the effects of the tight financial situation were obvious. Many teams brought back a modified second year car, incurring the Design Event penalties that incurs.

These included heavyweight team UWA, who could conceivably have won the event without this penalty.

The second year cars meant many more teams came to the event having tested beforehand. For the first time ever, every car entered at the event ran in one or more dynamic events. Of course, the later date gave a couple of weeks extra time to teams. The late date seems to have been popular, so we may well see it adopted as the standard date for future Aussie comps.

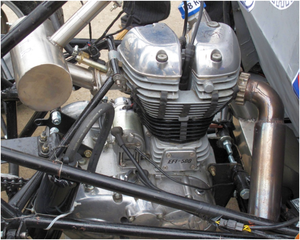

T he Indian team from Roorkee just managed to pass the brake test in time to compete in the second enduro. I was interested to see this car run as it was the first time we have seen the new generation India Enfield EFI500 engine run.

he Indian team from Roorkee just managed to pass the brake test in time to compete in the second enduro. I was interested to see this car run as it was the first time we have seen the new generation India Enfield EFI500 engine run.

This is a simple aircooled single cylinder engine fitted with electronic fuel injection and a unit construction crankcase containing the transmission. I have been recommending this engine to the Indian teams for a couple of years because import regulations there make it virtually impossible for them to source one of the more usual Japanese or European motorcycle engines.

The engine is a more basic design and somewhat bigger and heavier than the popular Yamaha and Honda units, but it is fitted with a simple management system that permits the user to incorporate the mandatory 20mm intake restrictor. In the event, the EFI-500 ran reliably but the lack of experience by the drivers meant a true measure of the engine’s performance was not obvious.

Monash won the event for the third successive year. This team have really optimised the points return per event to their benefit and were very worthy winners. Their 2011 car is a radical difference for their previous evolutions.

The team changed from a 4 cylinder engine to an Austrian KTM single and designed a significantly different chassis around it. Sensible and straightforward are words I would use to describe this car. The team stressed on getting the car finished early in order to do some exhaustive testing.

Isometric view of Monash chassis

At just over 200kg, the car was a little heavy for a ‘single’ but the team willingly accepted this penalty in order to get the first of this new evolution on the track and ensuring it was reliable. Very sensibly, they reasoned that the time lost accelerating an additional 20kg or so around the track could easily be nullified by testing and chassis optimisation.

Monash on track

The 2011 FSAE rules relaxed the limitations on Aerodynamic devices and Monash took full advantage. Again, they mounted their wings ‘live’ meaning the aero download is fed directly into the tyres rather than via the chassis.

Pre event research had the team change from their more usual Avon tyre choice to Goodyear and abandoned the spool drive system used in their previous two winners for a German Drexler clutch type limited slip differential. Both these decisions were made after investigation showed a points advantage over the entire spread of dynamic events.

On track, the Monash car was awesome, arguably the fastest car there and in my opinion, probably one of the very fastest FSAE cars in the world! The team were one of the four Design Finalists and scored well in all other events. All in all, a very worthy winner.

I was personally very pleased to see the Monash win. I like that it demonstrated that a team does not need a complex composite monocoque chassis to win in FSAE.

Other Design Finalists were RMIT, Auckland and the Design winners Edith Cowan University from Perth. The RMIT and Auckland cars were reasonably similar in concept, both small composite chassis powered by 450cc single cylinder Yamaha engines, though RMIT were on 10” wheels and Auckland on 13”.

Technically, the Auckland car was the more interesting, In order to effectively run a narrow track and reduce the yaw inertia as the car negotiates the slalom sectors of the circuit, the team re-engineered the power train to lower the c/g. They designed a transaxle system to replace the more normal chain drive arrangement (as used by the RMIT car). On track, especially in the wet, the Auckland car looked brilliant, but in the final washout, the Design Judges could not justify the additional 40kg weight penalty, so the RMIT car was awarded second place in Design, just a few points ahead of the Kiwi car.

Anxious Auckland students chasing a ‘hard start’ problem.

Design winning team Edith Cowan University brought the ‘other car with big wings’. In the case of ECU, however, the wings were mounted to the chassis rather than the suspension. On the track, one could see the team need to do some more development on their chassis setup as the car was seen to be porpoising quite a bit.

Technically, the ECU car was lovely. A simple folded composite main chassis mated to a space-frame rear section to carry the engine. The Honda CB600R engine was the only four cylinder engine in the Design Finals, an indication of how the competition has changed in recent years.

The standard of fit and finish was very high and the students really understood the design decisions they had made. The judges really had reservations about a couple of aspects of the car. Maybe about 10kg too heavy, some questions asked about feeding the braking torque into the monocoque structure, and the fact the aero package was ‘added on’ rather than ‘designed in’. We felt this was partly responsible for the on track behaviour mentioned above. Having said that, this reasonably inexperienced team were very competitive on track and along with their good performance in the static events, they finished in third place overall.

ECU Brabham tribute car on track

In each of their three years, the ECR team have had an historic theme, in previous years presenting their cars in JPS and Gulf Oil liveries. This year, the team paid homage to the Brabham marque, in particular the 1966 BT19 World Championship winning car, although I don’t think Event Design Patron Ron Tauranac was enamoured with the big wings, however he did admire some of the impeccable engineering in the car.

There were three visiting teams from Japan, our old friends from Tokyo Denki with the latest iteration of their lovely little Honda powered space-frame car running on 10” tyres, along with entries from Nippon Institute of Technology and Osaka University.

The NIT car, looking a little like an orange Tokyo Denki car, was powered by a 500cc twin cylinder Yamaha engine driving through a CVT transmission.

The Osaka car, painted in Kawasaki acid green and powered by a 600cc four cylinder Kawasaki Ninja engine, sounded like it had been tuned for absolute power rather than driveability and economy. The engine didn’t want to idle under what sounded like 8,000rpm and the rear sprocket was probably the biggest I have seen on a FSAE car. Not unexpectedly, they ran out of fuel about 100 meters from the finish of their enduro run, but managed to finish on the starter motor, to the delight of the onlookers. Strictly speaking that’s not allowed, but they had come a long way and lost a lot of time, so the judges ‘looked the other way’.

Other interesting sights at the competition

University of Western Australia turned up with some interesting wheel fairings.

The technical inspectors did not accept over the legality of such fairings on an ‘Open wheel race car’ as required by the rules so the team were politely asked to remove them.

The technical inspectors did not accept over the legality of such fairings on an ‘Open wheel race car’ as required by the rules so the team were politely asked to remove them.

Veteran driver Pete ‘the Pirate’ Marsh was devastating on track, fairings or no fairings, pulling the team up to a second place overall finish.

I expect to see some big changes in this team next year, probably another heavyweight team to go down the ‘single’ route.

Spool drives were quite common, although previous spool user Monash had abandoned theirs for a Drexler clutch type LSD.

Spool drive on the Uni of Newcastle car

It is easy to be dismissive of spool drives as a low buck solution, used only by teams with a low budget, however, in Australia, this is not quite the case. V8 Supercars use a spool and in many cases the students are willing to use this solution in order to gain experience that may help them obtain a job in V8 racing.

Personally, I have no objection to a spool as the students must further their understanding of vehicle dynamics in order to make one work.

Two electric cars ran at FSAE-A

RMIT ran a second entry for an electric car, the 3rd. iteration of their electric program.

The car was similar to their IC car, but powered by two electric motors, permitting torque vectoring.

Swinburne University have abandoned their successful IC FSAE program to pursue an electric program. This car, their second, was less complex than the RMIT car, being powered by a simple single motor, though the team had reworked it in a quest for more performance.

Both cars performed adequately and finished endurance, but were never a threat to the IC cars.

So, that was FSAE-A for 2011!

Design Error of the month

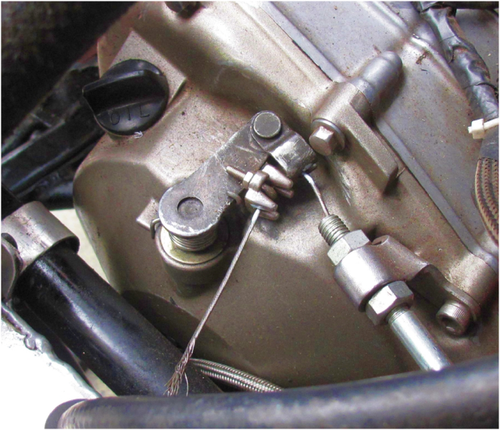

Seeing as this column has been a report of FSAEA 2011, I will show something from that event, but I will be careful to ensure I don’t identify the team involved.

Strictly speaking, this is not a Design Error, rather, it is an incorrect use of a component. Look at the termination of the clutch cable and the angle it causes the cable to pull through. Both things will lead to cable failure, something the team admitted to.

This sort of thing is okay as a temporary patch up if the correct cable cannot be found or as a field repair when testing, but a team should not bring this type of ‘engineering’ before the Judges.

I am busy writing a new tech column, Pat’s Seven Deadly Design Sins, so you won’t have to wait so long for the next column from Pat D’Rat