Welcome again to Pats periodic ramble. The holiday season is all over and a new year has begun. Best wishes to all teams for the new season, and lets make FS Germany 2006 the best FSAE or FS event in the world.

FSAE-A was successfully run in December last, and again the quality of the Australian teams just keeps getting better. Hopefully we will see some of those teams at Hockenheim in August. You can see my pix of the Australian event at http://evilallianceracing.com/ipw-web/gallery/FSAE-AUS05/ thanks to The Evil Alliance website. Some other interesting stuff there too.

Pat’s Design Errors No. 3

Many Formula teams are not aware that the biggest single force generated in the car is the front brake torque. Unless a team uses inboard front brakes (Unlikely) they have to understand how to react that brake torque into the primary chassis structure via the suspension components.

If you consider in simple terms what happens, it is easier to understand.

When the brakes are applied, the stationary caliper attempts to lock itself to the rotor. The caliper mounts and upright must be properly designed to accept this force repeatedly without failure. This is particularly true of machined aluminium uprights.

Similarly, the rotor mount and wheel hub must be designed for the job.

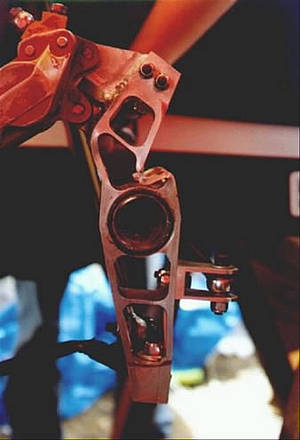

Fig 1. Distorted front upright.

It can be seen where the brake torque has overcome the integrity of this CNC’d upright. A simple diagonal web instead of the horizontal webs seen here might have avoided this failure. But look at the other picture before accepting that advice.

The load path from the upright to the chassis structure should direct and simple. As we discussed in DE1, feeding suspension and brake forces through threaded shafts in bending is not acceptable. Neither is chassis brackets that are flexible or poorly mounted. Judges have a good eye for this and will quickly appraise your design solution.

Fig 2. Failed upright and brake spider.

In this case, not only has the upright failed catastrophically, but the brake rotor spider has also failed

If you have a composite chassis structure, be prepared to show the judges proof of the effectiveness of your design.

The problem at the rear of the car is usually not so critical as most cars feed the brake torque and the engine torque into the chassis inboard of the suspension, and if the brakes are mounted outboard, the torque generated is usually only about one third of the front wheel torque.

That’s all for this month

Regards

Pat